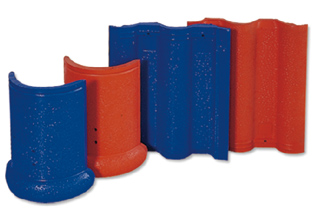

The QFW-120 is a specialized Colored Roof Tile Molding Line designed for premium tile production. Utilizing advanced hydraulic press-and-sieve technology, it produces high-density, leak-proof, and aesthetically superior cement tiles at a steady speed of 7-8 pieces per minute.

Superior Tile Density:Adopts Hydraulic Forming technology which exerts immense pressure to filter out excess water. This results in tiles with exceptional density, high frost resistance, and low water absorption, far superior to traditional rolled tiles.

Intelligent PLC Control:The entire operation is managed by a centralized PLC system, ensuring a consistent and reliable running cycle. It minimizes manual intervention while guaranteeing precise dimensions for every tile produced.

Robust & Durable Build:Constructed with a heavy-duty frame using high-intensity steel and advanced heat treatment. The molds undergo carburizing, nitriding, and quenching (HRC52-61), ensuring long service life even when processing abrasive materials like fly ash and waste residue.

The professional choice for manufacturing durable, high-quality, and market-competitive concrete roof tiles.

| Availability: | |

|---|---|

| Quantity: | |

QFW-120

Qunfeng

Product Description

Tech: High-Pressure Hydraulic Forming

Adopts advanced filtration molding technology. This ensures high tile density and creates a compact structure that far exceeds the quality of traditional rolled tiles.

Tech: Ultra-Low Water Absorption

The high-pressure forming process guarantees excellent frost resistance and ultra-low water absorption, providing reliable leak-proof performance for roofing applications.

Tech: Full PLC Control System

The complete operation is fully automated via PLC. This ensures a consistent running cycle and uniform quality for every batch, minimizing human error.

Tech: Heat-Treated Frame

Constructed using high-intensity steel and advanced heat treatment processes. This provides superior stability and exceptional wear resistance under high-pressure working conditions.

Tech: HRC52-HRC61 Hardness

Molds undergo carburizing, nitriding, and quenching to achieve a surface hardness of HRC52-HRC61, guaranteeing exceptional durability even with abrasive raw materials.

Tech: Waste Material Compatibility

Capable of producing high-quality tiles using fly ash and waste residue. This enables sustainable manufacturing and significantly reduces raw material costs.

Comparison of core parameters and competitive advantages based on official Qunfeng data.

| Technical Data | QFW-120 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Forming Speed | 7 - 8 pcs / min | Steady Output:Delivers a consistent production rate of roughly 480 tiles per hour, balancing speed with the high pressure required for premium quality tiles. |

| Forming Method | Press and Sieve (Hydraulic) | Superior Density:Unlike simple roll forming, this hydraulic "Press and Sieve" method filters out excess water, ensuring high density, frost resistance, and leak-proof performance. |

| Roof Tile Dimension | 424 × 337 mm | Standard Precision:Designed to produce standard 424x337mm tiles with high dimensional accuracy, ensuring easy installation and perfect interlocking on the roof. |

| Total Power | 7.5 kW | Energy Efficiency:Operates with a highly efficient 7.5 kW motor system, significantly reducing electricity costs per tile compared to larger, power-hungry production lines. |

| Machine Dimensions | 3200 × 1600 × 2600 mm | Compact Footprint:With a footprint of just ~5.1 square meters, this compact machine is easy to install in small workshops or add to existing production facilities. |

Application

|

|

Customer Case

|  |  |  |

| Vietnam | Dubai | Japan | Japan |

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian