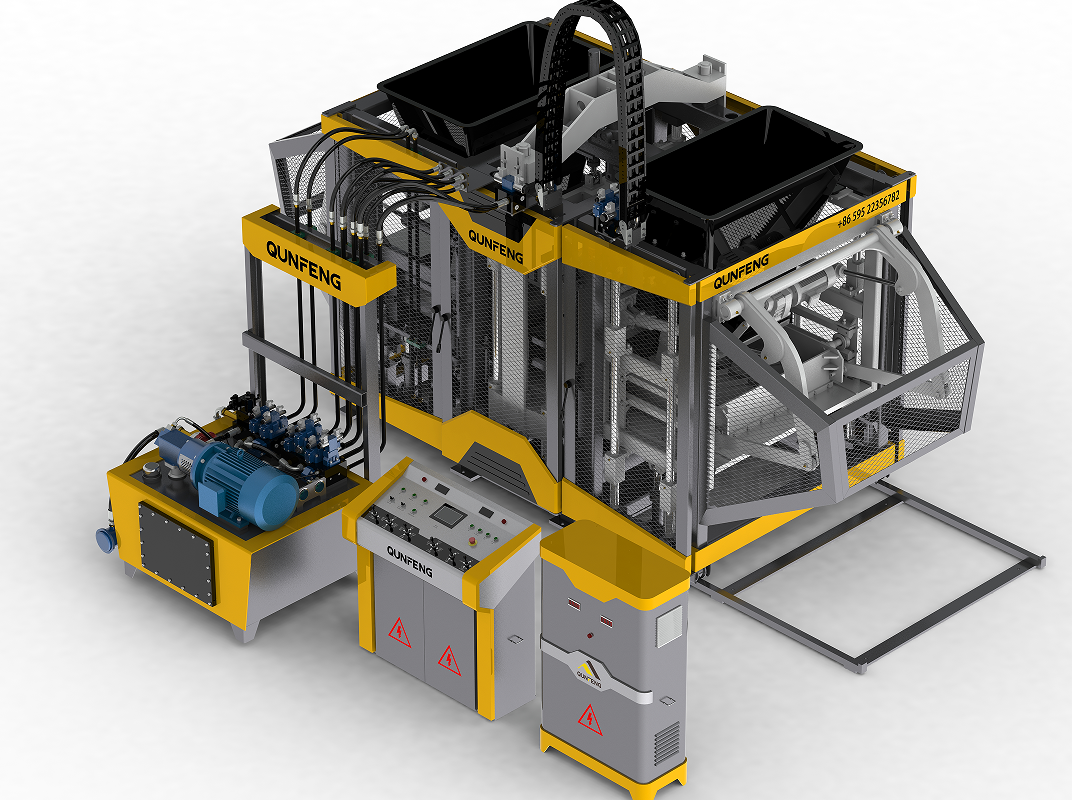

The QS1000 is an efficient and dependable solution tailored for small to medium-scale block production. Integrating advanced servo technology with a robust construction, it delivers high-quality output and rapid cycle times.

| Availability: | |

|---|---|

| Quantity: | |

QS1000

Qunfeng

Product Description

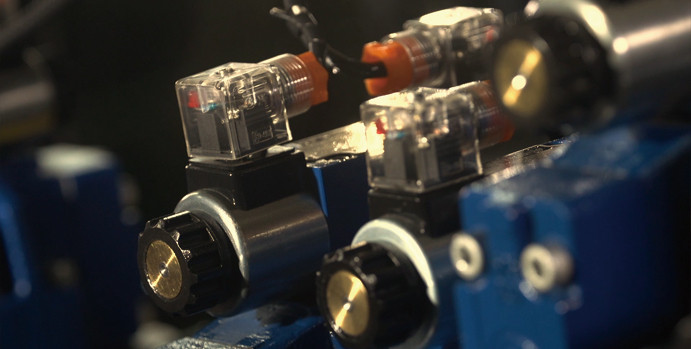

Tech: Electro-Hydraulic Integration + Servo Vibration

Combines advanced electro-hydraulic integration with high-speed servo vibration. This synergy delivers quick response times and precise movements, resulting in a 20% increase in output compared to standard hydraulic machines.

Tech: Siemens PLC + Remote Cloud Diagnosis

Powered by Siemens high-speed processing cores for micro-second synchronization. Features remote cloud diagnosis, allowing 90% of maintenance issues to be diagnosed instantly from anywhere, minimizing downtime.

Tech: Airbag Clamping + Michelin Rubber Pads

Utilizes imported Michelin raw rubber pads and an airbag clamping system. This effectively isolates vibration, reducing noise pollution by 10% while extending the service life of the mold and frame.

Tech: 360° Rotary Rake + Anti-Mix Color System

The 360° multi-bar rotating rake ensures rapid, uniform density filling. The specialized Anti-mixing Pigment Feeding System guarantees distinct color separation for high-end pavers.

Tech: Heat Treatment + High-Strength Steel

The main frame undergoes rigorous heat treatment and vibration aging to eliminate internal stress. This ensures the machine remains stable and deformation-free even after years of high-intensity operation.

Tech: Quick Mold Change + Wide Applicability

Engineered for flexibility. The QS1000 can easily switch molds to produce everything from standard hollow blocks and solid bricks to complex pavers and curbstones, meeting diverse market demands.

9 Major Components for The Servo Block Machine | ||

Efficient Servo System |  Stabile Hydraulic System |

Dumping Airbag |

The design for the press head with two oil cylinders |

Air-operated Clean Device |

Ping-pong type for feeding material |

Arc-shape Feeding Arm |

Modularize Eccentric Vibration |

Automatic Control System |

Comparison of core parameters and competitive advantages against industry standards.

| Technical Data | QS1000 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Pallet Size | 1100 × 870 mm | Optimized Capacity:Larger surface area than the QS700/800 series, specifically designed to increase per-batch output for medium-to-large scale projects. |

| Molding Cycle | 9-18 sec | Rapid Production:High-efficiency hydraulic valves shorten the molding cycle, delivering 15% higher daily turnover compared to standard machines in this class. |

| Vibration Frequency | 0-75 Hz | High-Density Compaction:Servo-controlled vibration ensures raw materials are aggressively compacted, resulting in blocks with superior compressive strength and finish. |

| Rating Pressure | 21 MPa | Industrial Forming Power:Provides consistent high pressure to ensure tight aggregate bonding, ideal for producing heavy-duty pavers and load-bearing hollow blocks. |

| Total Power | 50.1 kW | Energy Efficient Design:The optimized power system reduces energy waste. While offering higher output than smaller models, it maintains a low electricity cost per unit produced. |

| Main Machine Dimension | 3150 × 2400 × 3500 mm | Robust Structural Integrity:The heavy-duty frame is heat-treated to resist deformation, ensuring stability during high-frequency vibration and extending machine lifespan. |

| Legend | Product size (mm) | Pcs./Pallet | Pcs./Hour | ||

| 240*115*53 | 44 | 10500-14000 | |||

200*100*60 | 27 | 4400-4800 | |||

225*112.5*60 | 24 | 3900-4300 | |||

390*140*190 | 8 | 1600-1900 | |||

| 400*200*200 | 7 | 1400-1700 | ||

Note: The molding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw material.

Production Line

Simple Block Making Production Line(Single Line) | ||||

|

Fully Automatic Block Making Production Line | ||||

|

Fully Automatic Block Production Line with Curing Rack | ||||

|

Application

Building Wall Material Series | ||

Flower Bed Brick |  Split Brick |  Split Brick |

Split Brick |  Wall Brick |  Solid Brick |

Paving Stone Series | |||

Permeable Brick |

|

Antique Brick |

Antique Brick |

Antique Brick |

Antique Brick |

Chain Pavement |

Chain Pavement |

Pavement Brick |

Antique Brick |

Antique Brick |

|

|

|

|

Split Brick, Pavement Brick |

Grass Brick |

Grass Brick |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Road Wdge Stone Series | |||

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone | |

Slope-protect Brick Series | |||

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick | ||

Customer Case

Gansu |

India | ||

Mozambique |

IvoryCoast | ||

Lianyungang |

Nantong |

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian