The QF400 is a smart investment choice for startups and small-scale manufacturers. Combining a compact footprint with powerful double-motor vibration technology, it delivers high-quality hollow blocks and pavers with minimal operational complexity.

Low Investment, High Return:Engineered for cost-efficiency, offering a short molding cycle (12-25s) and high daily output, ensuring a rapid return on investment for new businesses.

Compact & Versatile:Despite its small size, it supports a wide production range with block heights from 50mm to 250mm, easily switching between hollow blocks, solid bricks, and pavers.

Simplified Operation:Features a streamlined hydraulic system that is easy to operate and maintain, reducing the need for highly specialized labor while maintaining excellent performance.

The perfect entry-level solution for producing high-quality concrete products with a limited budget.

| Availability: | |

|---|---|

| Quantity: | |

QF400

Qunfeng

Product Description

Tech: Low Capital Cost + Fast Payback

Designed specifically for startups. Its optimized structure minimizes initial investment while maintaining high production speed, ensuring a rapid return on investment within a short period.

Tech: Multi-Purpose Molding System

Despite its compact size, the QF400 supports a wide range of products. By simply changing molds, it can produce hollow blocks, solid bricks, pavers, and curbstones (Height: 50mm - 250mm).

Tech: Vertical Directional Vibration

Utilizes advanced vertical directional vibration technology. This ensures superior vibration transmission to the mold box, resulting in blocks with higher density and strength compared to standard mechanical machines.

Tech: Simplified Hydraulic Control

Features a streamlined control system that is intuitive and easy to master. This reduces the dependency on highly skilled technicians and simplifies daily maintenance and troubleshooting.

Tech: Waste Utilization Capability

Engineered to effectively utilize various raw materials, including fly ash, slag, and construction waste. This significantly lowers raw material costs while promoting eco-friendly production.

Tech: Heat Treatment + Wire Cutting

All molds undergo rigorous Carbonitriding heat treatment and precision wire cutting. This ensures exceptional wear resistance and extends the service life of the mold by up to 50%.

Major Components for The Servo Block Machine | |

Vibration system |  Material feeding system |

Hydraulic system |

Pallet conveyor |

Comparison of core parameters and competitive advantages against industry standards.

| Technical Data | QF400 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Pallet Size | 680 × 535 mm | Smart Compact Design:Optimized for small-scale production, this size minimizes the cost of auxiliary pallets while ensuring sufficient output for startup businesses. |

| Molding Cycle | 12-25 sec | Efficient Turnover:Despite its small size, the QF400 offers a competitive cycle time, ensuring steady daily output and faster project completion. |

| Vibration Frequency | 0-68 HZ | Effective Compaction:Synchronous vibration technology ensures uniform density for every block, meeting quality standards typically reserved for larger machines. |

| Rating Pressure | 8 MPa | Reliable Hydraulic Power:The simplified hydraulic system provides consistent 8MPa pressure, perfect for producing standard hollow blocks and pavers with low maintenance needs. |

| Total Power | 21.45 kW | Low Energy Consumption:Highly energy-efficient design significantly lowers electricity bills, maximizing the profit margin for every block produced. |

| Main Machine Dimension | 2800 × 1160 × 3040 mm | Space-Saving Footprint:Compact vertical structure occupies minimal floor space, allowing for flexible installation in small workshops or limited factory areas. |

| Suitable Block Height | 50-250 mm | Versatile Production:Capable of producing a wide range of products from thin pavers (50mm) to large hollow blocks (250mm), offering great market adaptability. |

| Legend | Product size (mm) | Pcs./Pallet | Pcs./Hour | ||

| 240*115*53 | 20 | 5100-6000 | |||

200*100*60 | 10 | 1600-1800 | |||

225*112.5*60 | 10 | 1600-1800 | |||

390*140*190 | 4 | 800-900 | |||

| 400*200*200 | 3 | 600-700 | ||

Note: The molding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw material.

Production Line

Application

|  |  |  |

| Flower Bed Brick | Split Brick | Split Brick | Split Brick |

|  |  | |

| Wall Brick | Solid Brick | Wall Tiles |

Paving Stone Series

|  |  |  |

Permeable Brick | Permeable Brick | Antique Brick | Antique Brick |

|  |  |  |

Antique Brick | Antique Brick | Chain Pavement | Chain Pavement |

|  |  |  |

Pavement Brick | Antique Brick | Antique Brick | Pavement Brick |

|  |  |  |

Pavement Brick | Pavement Brick | Pavement Brick | Split Brick, Pavement Brick |

|  |  |  |

Grass Brick | Grass Brick | Paving Stone | Paving Stone |

|  |  |  |

Paving Stone | Paving Stone | Paving Stone | Paving Stone |

|  |  |  |

Paving Stone | Paving Stone | Paving Stone | Paving Stone |

Road Wdge Stone Series

|  |  |  |

Road Wdge Stone | Road Wdge Stone | Road Wdge Stone | Road Wdge Stone |

|  |  | |

Road Wdge Stone | Road Wdge Stone | Road Wdge Stone |

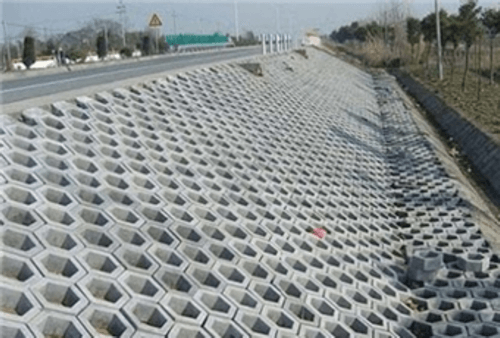

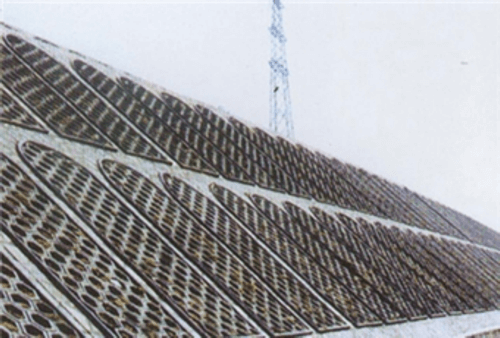

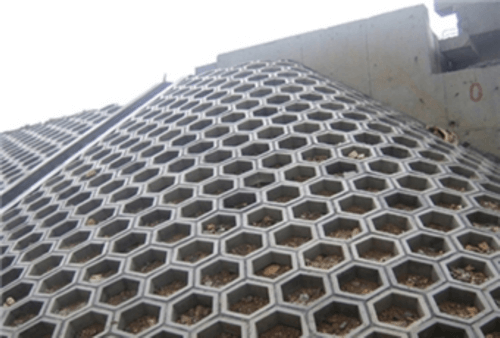

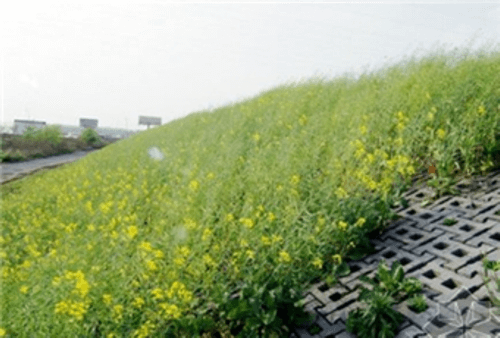

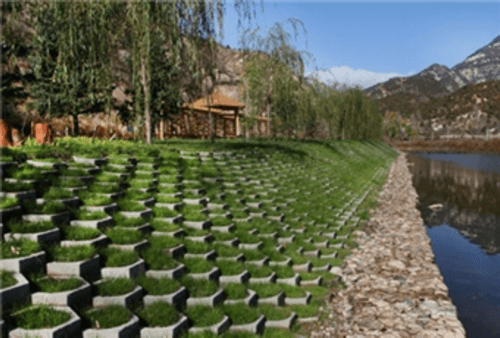

Slope-protect Brick Series

|  |  |  |

Slope-protect Brick | Slope-protect Brick | Slope-protect Brick | Slope-protect Brick |

|  |  |  |

Slope-protect Brick | Slope-protect Brick | Slope-protect Brick | Slope-protect Brick |

|  | ||

Slope-protect Brick | Slope-protect Brick |

Customer Case

|

| Philippines |

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian