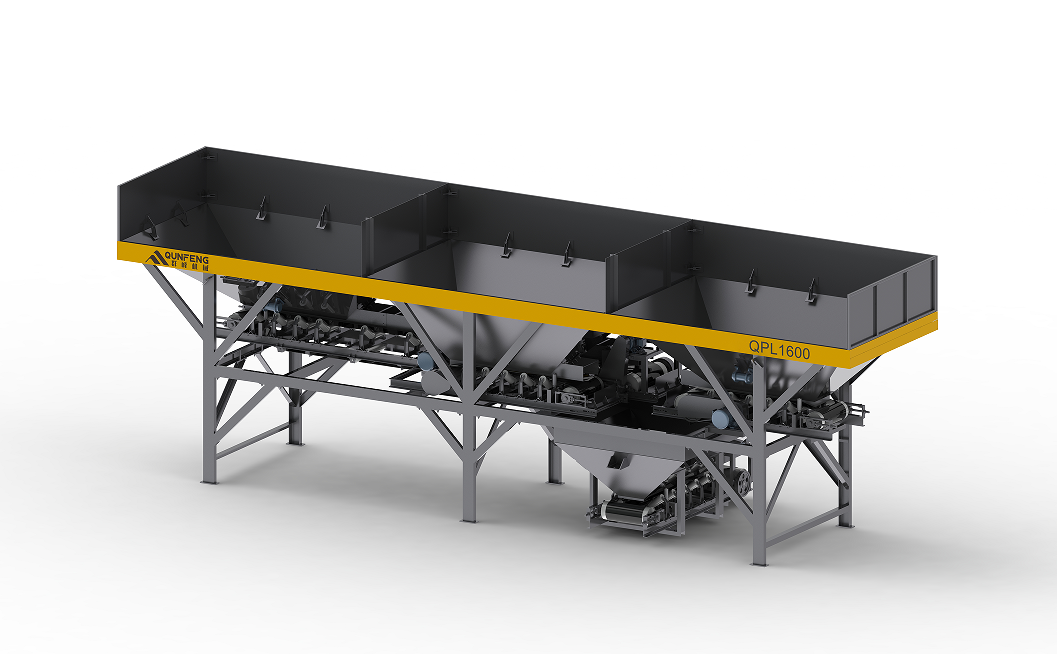

The QPLD1600 is a heavy-duty 3-bin batching system engineered for large-scale concrete production. With a 1.6m³ weighing capacity and a robust 96 m³/h productivity, it provides the massive material throughput required by high-capacity block machines and mixing plants.

Industrial-Grade Productivity:Achieves a high output of 96 m³/h, ensuring a relentless supply of aggregate. Its upgraded 3000 kg maximum weighing capacity handles heavy loads with ease, reducing cycle frequency.

Large-Scale Storage:Features a 3-bin configuration with substantial 3×6 m³ reserve hoppers. This expanded storage buffer minimizes loader operations and guarantees smooth, uninterrupted production shifts.

Precision Control System:Utilizes advanced electronic cumulative measurement to strictly maintain a batching precision of ±2%. The centralized PLC system ensures fully automated, error-free operation for consistent concrete quality.

The powerful, high-capacity solution for industrial-scale concrete manufacturing.

| Availability: | |

|---|---|

| Quantity: | |

QPLD1600

QUNFENG

Product Description

Tech: 96 m³/h Capacity

Engineered for large-scale production. It delivers a massive theoretical productivity of 96 m³/h, providing a relentless material supply for high-capacity block machines and mixing plants.

Tech: 3000kg Weighing Capacity

Features an upgraded 3000 kg maximum weighing capacity. This allows it to handle significantly larger batches per cycle, optimizing efficiency for heavy-duty industrial mixers (e.g., JS750/JS1000).

Tech: Electronic Cumulative Measurement

Adopts advanced electronic cumulative measurement technology. This ensures high measurement precision of ±2%, guaranteeing the structural integrity of every concrete batch.

Tech: PLC + Digital Display

Equipped with a PLC centralized control system and a clear digital display. It offers fully automated operation, reducing manual labor and potential errors.

Tech: 3×6m³ Reserve Hoppers

Designed with substantial 3×6 m³ reserve hoppers. This expanded storage buffer reduces the frequency of loader refilling, ensuring smooth, uninterrupted production shifts.

Tech: Multi-Equipment Support

The feeding system is highly compatible with loading machines, belt conveyors, and grab buckets. Its 3-bin layout supports complex mix designs (e.g., Sand, Stone, Chips).

Comparison of core parameters and competitive advantages based on official Qunfeng data.

| Technical Data | QPLD1600 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Theoretical Productivity | 96 m³/h | Industrial Throughput:Achieves a massive output of 96 cubic meters per hour, specifically engineered to feed large-scale block machines (e.g., QS1300/QS1500) without bottlenecks. |

| Max. Weighing Capacity | 3000 kg | Heavy-Duty Scaling:Upgraded to handle a maximum load of 3000 kg per batch. This robust capacity is essential for processing high-density aggregates and large concrete volumes. |

| Weighing Hopper Capacity | 1.6 m³ | Large Batch Size:Features a 1.6 m³ weighing hopper, allowing for significant material throughput per cycle, reducing the frequency of batching cycles needed to meet targets. |

| Reserve Hopper Configuration | 3 × 6 (Units/Size) | Expanded Storage:Utilizes a 3×6 configuration, providing a substantial material buffer. This minimizes loader operations and ensures continuous production even during peak hours. |

| Batching Categories | 3 Types | Flexible Mix Designs:Supports 3 distinct aggregate bins, allowing for versatile concrete recipes (e.g., mixing sand, gravel, and stone dust) required for premium pavers. |

| Batching Precision | ± 2% | High Accuracy:Despite its heavy-duty capacity, it maintains a strict ±2% precision, ensuring consistent concrete quality and reducing raw material wastage. |

| Loading Height | 2580 mm | Optimized Logistics:Designed with a loading height of 2580 mm, making it compatible with standard wheel loaders and eliminating the need for excessively high ramps. |

| Total Power | 10.35 kW | Energy Efficient:Operates with a total power of 10.35 kW, delivering high performance with optimized energy consumption for lower operational costs. |

| Dimensions (L×W×H) | 9600 × 2730 × 3035 mm | Robust Footprint:The substantial 9.6m length accommodates the larger 3-bin system and weighing mechanisms required for industrial-scale batching. |

Customer Case

Egypt |

Brazil |

Ghana |

Qatar |

Bangladesh |

Vietnam |

China |

China |

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian