| Availability: | |

|---|---|

| Quantity: | |

QS1500

Qunfeng

Product Description

Tech: 4-Axis Servo Vibration System

Features a high-efficiency 4-axis servo system that delivers strong excitation force and fast response. This ensures superior density and stability, especially for heavy-duty blocks.

Tech: 35mm - 300mm Height Capacity

Unmatched versatility. The QS1500 can produce everything from thin pavers (35mm) to massive curbstones (300mm), allowing you to enter high-margin niche markets.

Tech: Siemens PLC + 5G Local Caching

Powered by Siemens PLC with Local Data Caching. Critical diagnostic data is never lost even in weak-signal remote sites, reducing troubleshooting time by 30%.

Tech: Airbag Clamping + Auto-Change

Combines airbag clamping with an auxiliary auto-change system. Allows for switching production types in under 20 minutes, maximizing operational agility.

Tech: 360° Rotary Rake + Anti-Mix

The 360° rotating rake ensures uniform density, while the specialized anti-mix system guarantees crisp, distinct colors for high-value landscape pavers.

Tech: Heat-Treated Molds (5M Cycles)

Equipped with Heat-Treated Mold Plates and Hardened Guide Pillars. Rigorously tested for 5 million cycles without precision loss, ensuring long-term value.

Tech: Imported Michelin Rubber Pads

Utilizes imported Michelin rubber pads for high-efficiency damping. This reduces noise pollution, protects the frame, and creates a safer work environment.

Tech: Space Optimization + Energy Saving

Engineered to reduce factory footprint by 15%. Smart power distribution lowers electricity consumption, balancing high output with operational efficiency.

Tech: Solid Waste Utilization

Optimized to transform industrial waste (tailings, construction waste) into high-strength products, meeting global ESG standards and maximizing ROI.

Tailings-to-Profit Specialist:Optimized for high-abrasion materials like iron ore tailings and marble dust, extending mold life by 20% through smart vibration control.

9 Major Components for The Servo Block Machine | ||

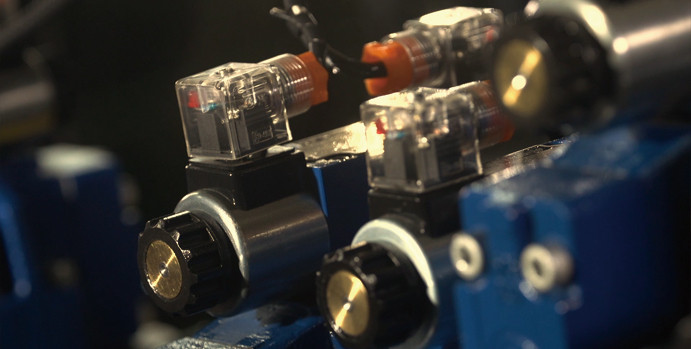

Efficient Servo System |  Stabile Hydraulic System |

Dumping Airbag |

The design for the press head with two oil cylinders |

Air-operated Clean Device |

Ping-pong Type for Feeding Material |

Arc-shape Feeding Arm |

Modularize Eccentric Vibration |

Automatic Control System |

Comparison of core parameters and competitive advantages against industry standards.

| Technical Data | QS1500 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Molding Cycle | 11-19 sec | Ultra-High Speed: Significantly faster than the standard 20-25s cycle, maximizing daily throughput for high-volume paver production. |

| Vibration Frequency | 0-75 Hz | High-Speed Servo: Wider frequency range than the 50Hz industry standard, achieving faster compaction and higher block density. |

| Rating Pressure | 21 MPa | High-Pressure Molding: Ensures superior load-bearing strength and durability for heavy-duty blocks and pavers. |

| Suitable Block Height | 35-300 mm | Versatile Production: Optimized range for both thin decorative pavers (35mm) and standard road curbstones (up to 300mm). |

| Pallet Size | 1400 x 1000 mm | Optimized Efficiency: A balanced size that supports high output while maintaining energy efficiency for medium-to-large plants. |

| Total Power | 87.1 kW | Energy Saving: Advanced servo technology reduces power consumption by 20-30% compared to traditional hydraulic systems. |

| Dimension (Main Machine) | 3400 x 2700 x 3775 mm | Compact Footprint: Efficient structural design allows for easy installation in existing factory layouts. |

Note: The molding cycle time and hourly capacity may vary based on raw material quality and product type.

| Legend | Product size (mm) | Pcs./Pallet | Pcs./Hour | ||

| 240*115*53 | 70 | 17000-21000 | |||

200*100*60 | 48 | 7700-8500 | |||

225*112.5*60 | 40 | 6400-7100 | |||

| 390*140*190 | 18 | 3600-4300 | ||

| 400*200*200 | 12 | 2400-2900 | ||

Note: The moulding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw material.

Production Line

Simple Block Making Production Line(Single line) | ||||

|

Fully Automatic Block Making Production Line | ||||

|

Fully Automatic Block Production Line with Curing Rack | ||||

|

Application

Building Wall Material Series | ||

Flower Bed Brick |  Split Brick |  Split Brick |

Split Brick |  Wall Brick |  Solid Brick |

Paving Stone Series | |||

Permeable Brick |

|

Antique Brick |

Antique Brick |

Antique Brick |

Antique Brick |

Chain Pavement |

Chain Pavement |

Pavement Brick |

Antique Brick |

Antique Brick |

|

|

|

|

Split Brick, Pavement Brick |

Grass Brick |

Grass Brick |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Paving Stone |

Road Wdge Stone Series | |||

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone |

Road Wdge Stone | |

Slope-protect Brick Series | |||

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick |

Slope-protect Brick | ||

Customer Case

Anhui |

Egypt | ||

Bengal |

Brazil | ||

Lianyungang |

Nantong |

The QPR600-6 is a premium Hermetic Wet Press Machine optimized with Italian technology. It features a unique rotating-disk design that enables independent station movement, ensuring superior stability and high-efficiency production of high-value decorative tiles.

High-Value Production:Specially designed to produce premium terrazzo tiles and imitation stone pavers. The wet press technology allows for deep processing (sandblasting, grinding), significantly increasing the market value of the final product.

Advanced Rotary Technology:Utilizes an optimized turntable operation mode where each movement is independent. This structure is more stable than traditional linear machines and delivers higher production efficiency (up to 520㎡/8h).

Versatile & Multi-Color:Capable of producing single-layer or double-layer tiles with complex multi-color patterns. Ideal for manufacturing high-end floor tiles, sidewalk pavers, and plaza stones.

The preferred choice for manufacturers targeting the high-end decorative paving market.

The Road Construction High-Speed Paver Laying Machine is engineered for efficient and rapid asphalt application, ensuring smooth, durable road surfaces. With advanced technology, it combines high-speed operation with precise, consistent results. Built for large-scale paving projects, its robust design minimizes downtime and maximizes productivity. Perfect for highways, roads, and infrastructure projects, this machine also offers versatility in laying various types of bricks, including concrete pavers, water-permeable pavement, and sintered road bricks. It can easily cover 400 to 500 square meters daily, making it an excellent choice for municipal engineering, garden construction, and other paving applications.

The Concrete Batching Machine QPLD1600 3200 2400IV is engineered for efficient and precise measurement and mixing of concrete ingredients. Offering various configuration options, this machine provides flexible solutions to meet diverse batching requirements. It guarantees accurate proportions of aggregates, cement, and water, ensuring consistent and high-quality concrete production. With its durable construction, it is perfectly suited for high-volume operations and can easily integrate into larger concrete production systems. The QPLD1600 3200 2400IV is user-friendly, reduces material waste, and enhances productivity in any concrete manufacturing facility.

The QPL Series Concrete Batching Machine and mixer are fully automated, designed for seamless operation. Featuring electronic cumulative measurement and PLC centralized control with a digital display, the system ensures high measurement precision, quick mixing speeds, and superior reliability. The feeding equipment is highly adaptable, compatible with various machines such as loaders, belt conveyors, grab buckets, and horizontal push systems.

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian