The QJS500 is a robust double horizontal shaft forced concrete mixer designed for professional-grade homogeneity. With an 800L feeding capacity and 500L output, it delivers powerful mixing action suitable for dry, plastic, and lightweight aggregate concrete, making it the core engine for efficient block making plants.

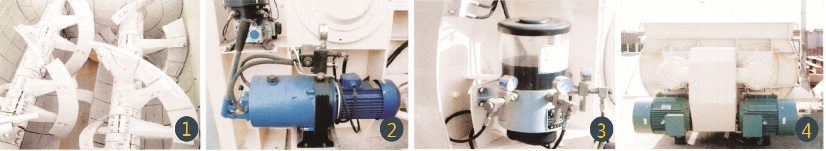

Double Shaft Forced Mixing:Utilizes a double horizontal shaft mechanism with 2×7 mixing vanes. This continuous screw mixing action guarantees superior uniformity and a shorter cycle time compared to single-shaft models.

High Productivity:Achieves a productivity rate of 25 m³/h, significantly boosting daily output. It integrates seamlessly with QPL800 or QPL1200 batching machines to form a complete, automated mixing station.

Advanced Heavy-Duty Design:Equipped with a hydraulic discharging system and an electric lubricating pump for concentrated oil supply. The planetary reducer transmission ensures smooth power delivery and long-term durability.

The durable, high-efficiency mixing powerhouse for demanding construction projects.

| Availability: | |

|---|---|

| Quantity: | |

QJS500

QUNFENG

Product Description

Tech: Double Horizontal Shaft + Screw Mixing

Features a double horizontal shaft forced mixer design with continuous screw mixing technology. This ensures intense agitation and superior homogeneity for all concrete types.

Tech: Hydraulic Discharging System

Equipped with a robust hydraulic discharging system. This provides controlled, powerful, and reliable unloading of the mixed concrete, minimizing residual waste.

Tech: Planetary Reducer Transmission

Utilizes a high-quality planetary reducer transmission. This ensures smooth power delivery, high torque output, and extended service life for the drive system.

Tech: Electric Lubricating Pump

Features a concentration oil supply system powered by an electric lubricating pump. This automates maintenance, ensuring critical components are always properly lubricated.

Tech: Multi-Concrete Compatibility

Capable of mixing diverse materials including harsh concrete, plastic concrete, liquid concrete, and lightweight aggregate concrete.

Tech: Mixing Station Ready

Can be used independently or combined with QPL800 or QPL1200 batching machines to form a complete, automated simple mixing station.

Comparison of core parameters and competitive advantages based on official Qunfeng data.

| Technical Data | QJS500 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Feeding Capacity | 800 L | Generous Input:Features an 800L feeding capacity, providing ample volume for aggregates and cement before mixing, ensuring the drum is utilized to its optimal potential. |

| Discharge Capacity | 500 L (Exceeding Capacity) | Standard 0.5m³ Batch:Delivers a consistent 500 liters (0.5 m³) of finished concrete per cycle, the industry-standard volume for medium-scale block machines, simplifying production planning. |

| Productivity | 25 m³/h | High Throughput:Achieves a robust productivity rate of 25 cubic meters per hour, significantly outperforming single-shaft mixers and meeting the demands of commercial projects. |

| Mixing Vane Speed | 30.5 r/min | Intense Agitation:The dual shafts rotate at a rapid 30.5 r/min, creating intense turbulence that ensures homogeneity even for dry-cast or stiff concrete mixes. |

| Mixing Vane Quantity | 2 × 7 (Double Shaft) | Double Shaft Coverage:Equipped with 14 mixing vanes in a 2×7 configuration. This double horizontal shaft design eliminates dead zones and reduces mixing time. |

| Max. Aggregate Diameter | 60 mm / 40 mm | Versatile Compatibility:Handles large aggregates up to 60mm (pebble) or 40mm (gravel), making it suitable for everything from road base to fine architectural precast. |

| Total Power | 25.5 kW | High-Torque Drive:Powered by a heavy-duty 25.5 kW motor system, providing the torque necessary to start under load and mix zero-slump concrete without stalling. |

| Total Weight | 4000 kg | Heavy-Duty Build:The massive 4000 kg structure dampens vibrations and ensures long-term durability in harsh industrial environments. |

| Working Dimensions | 5140 × 3000 × 5900 mm | Industrial Scale:With a substantial working height of 5.9 meters, it is designed to integrate perfectly with overhead batching systems and cement silos. |

Continuous screw mixing;

Hydraulic discharging system;

Concentration oil supply system of Electric lubricating pump;

Planetary reducer transmission.

Customer Case

Egypt |

Gabon |

Mali |

Sri Lanka |

Vietnam |

Vietnam |

Libya |

Kenya |

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian