The Qunfeng QS1300 is a high-performance automatic block machine engineered for large-scale commercial production. Powered by advanced electro-hydraulic servo technology, it achieves an ultra-fast molding cycle of 10 seconds, delivering significantly higher output and density than standard machines. It is the ultimate choice for high-capacity paver and block plants.

Core Technology:Servo Vibration (Energy saving & Noise reduction)

Production Speed:10 Seconds / Cycle (Supersonic Speed)

Large Pallet Size:1100 x 950 mm (Massive per-batch output)

Ideal For:Large-scale Paver & Hollow Block Plants.

| Availability: | |

|---|---|

| Quantity: | |

QS1300

QUNFENG

Product Description

Tech: Fully Automated PLC System

Powered by a fully automated Siemens PLC system, the QS1300 significantly reduces manual dependency, achieving a 15% saving in labor costs compared to standard semi-auto machines.

Tech: Rapid Dynamic Response

Advanced integration technology ensures rapid dynamic response and precise movements. This synchronization delivers a 20% increase in production output per shift.

Tech: Vibration Isolation Design

The unique suspension design effectively isolates vibration from the frame. This extends machine life and ensures a 10% reduction in noise pollution, creating a safer work environment.

Tech: Real-time Alarm System

Equipped with a real-time automatic fault alarm system. It identifies issues instantly and guides operators to the solution, delivering a 30% time saving in troubleshooting.

Tech: Intelligent Power Logic

The intelligent starting logic manages the power curve efficiently. This protects the motor and leads to a 20% improvement in overall working efficiency.

Tech: PLC Ratio Storage

Material ratio programs are stored directly in the PLC controller. This eliminates human error and ensures consistent block quality across every batch ("Zero Manual Interference").

Tech: Intelligent Cloud Connectivity

Qunfeng’s Intelligent Cloud connectivity allows our expert technicians to diagnose and solve software problems remotely for any location, maximizing uptime.

Tech: Customized Configuration

We provide tailored design configurations to match your specific production needs (from simple lines to fully automated plants), maximizing efficiency and ROI.

Tech: Space Optimization + Quick Changeover

Engineered to reduce factory footprint by 15% compared to standard lines. Features a fast-mold-change system that allows switching production types in under 20 minutes, maximizing operational agility.

Tech: Heat-Treated Molds + Hardened Pillars

Equipped with Heat-Treated Mold Plates and Hardened Guide Pillars. Rigorously tested for 5 million cycles without precision loss, ensuring long-term structural integrity and minimal maintenance.

Optimized for Sponge City Solutions (IKN Standards): The QS1300 is the industry benchmark for high-porosity permeable pavers, ensuring zero structural compromise while meeting the 2026 international water-drainage standards.

9 major components for the servo block machine | ||

|

|

|

|

|

|

|

|

|

Comparison of core parameters and competitive advantages against industry standards.

| Technical Data | QS1300 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Pallet Size | 1400 x 1200 mm | Massive Area: Extremely large molding area allows for maximum brick output per cycle (e.g., 54 standard bricks). |

| Cycle Time | 10-18 sec | Supersonic Speed: Servo-driven system ensures the fastest molding speed in its class, ideal for commercial production. |

| Vibration Frequency | 0 -75 Hz (Servo) | High Density: Adjustable high-frequency vibration guarantees superior compaction and strength for pavers and blocks. |

| Total Power | 60.6 kW | Optimized Power: Provides robust hydraulic pressure (21MPa) while maintaining energy efficiency via servo control. |

| Suitable Block Height | 35-300 mm | High Versatility: Capable of producing everything from thin decorative veneers (35mm) to large hollow blocks (300mm). |

| Rating Pressure | 21 MPa | Hydraulic Force: High pressure ensures fast forming and tight material compaction. |

| Dimension (L×W×H) | 3400×2350×3500 mm |

| Technical Data | QS1300 Specification | Competitive Advantage (vs Industry Standard) |

|---|---|---|

| Pallet Size | 1400 x 1200 mm | Massive Area: Extremely large molding area allows for maximum brick output per cycle (e.g., 54 standard bricks). |

| Cycle Time | 10-18 sec | Supersonic Speed: Servo-driven system ensures the fastest molding speed in its class, ideal for commercial production. |

| Vibration Frequency | 0 -75 Hz (Servo) | High Density: Adjustable high-frequency vibration guarantees superior compaction and strength for pavers and blocks. |

| Total Power | 60.6 kW | Optimized Power: Provides robust hydraulic pressure (21MPa) while maintaining energy efficiency via servo control. |

| Suitable Block Height | 35-300 mm | High Versatility: Capable of producing everything from thin decorative veneers (35mm) to large hollow blocks (300mm). |

| Rating Pressure | 21 MPa | Hydraulic Force: High pressure ensures fast forming and tight material compaction. |

| Dimension (L×W×H) | 3400×2350×3500 mm | Industrial Design: Robust structure designed for 24/7 continuous operation in large-scale plants. |

Note: Production capacity depends on the specific brick size and raw material mix.

| Legend | Product size (mm) | Pcs./Pallet | Pcs./Hour | ||

| 240*115*53 | 56 | 14000-17000 | |||

200*100*60 | 36 | 5900-6500 | |||

225*112.5*60 | 28 | 4600-5000 | |||

390*140*190 | 12 | 2400-2800 | |||

| 400*200*200 | 10 | 2000-2400 | ||

Note: The molding cycle time and the hourly capacity will be changed according to the proportion and the quality of the raw material.

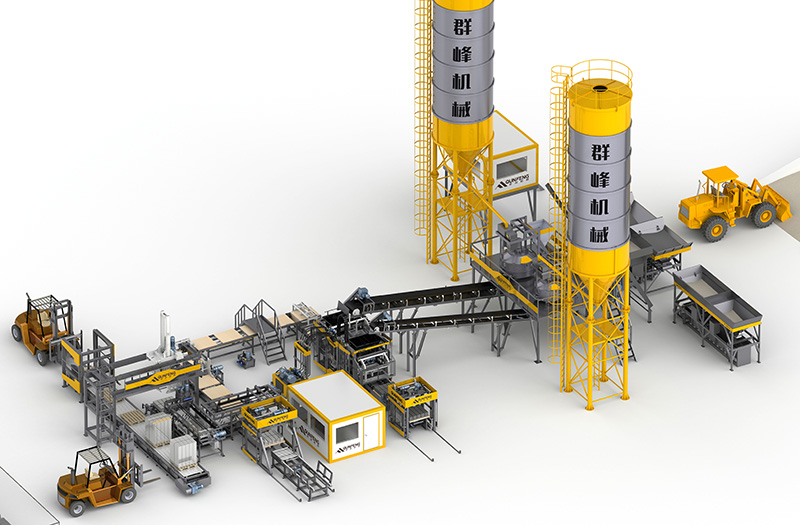

Production Line

Simple Block Making Production Line(Single line)

Fully Automatic Block Making Plant with Stacker

Fully Automatic Block Making Production Line

Fully Automatic Block Production Line with Curing Rack

Application

Building Wall Material Series

Flower Bed Brick |

Split Brick |

Split Brick |

Split Brick |

Split Brick |

Solid Brick |

Wall Tiles |

Wall Tiles |

Paving Stone Series

|

|

|

|

|  Antique Brick Antique Brick |

|

Chain Pavement |

|

|

|

|

|

|

|

Split Brick, Pavement Brick |

|

|

|  Paving Stone Paving Stone |

|

|

|

|

Road Wdge Stone Series

|

|

|

|

|

|

|

Slope-protect Brick Series

|

|

|

|

|

|

|

|

|

|

Customer Case

Building Wall Material Series

Russia |  Saudi Arabia |

Egypt |

Saudi Arabia |

Vietnam |

Vietnam |

Vietnam |

Vietnam |

India |

India |

China |  China |

China |

China |

China |

China |

China |

China |

China |

China |

/ / : +86-18150503129

Marketing Center : No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian